Description

Processing Line for Whitefish

Producer: Marel

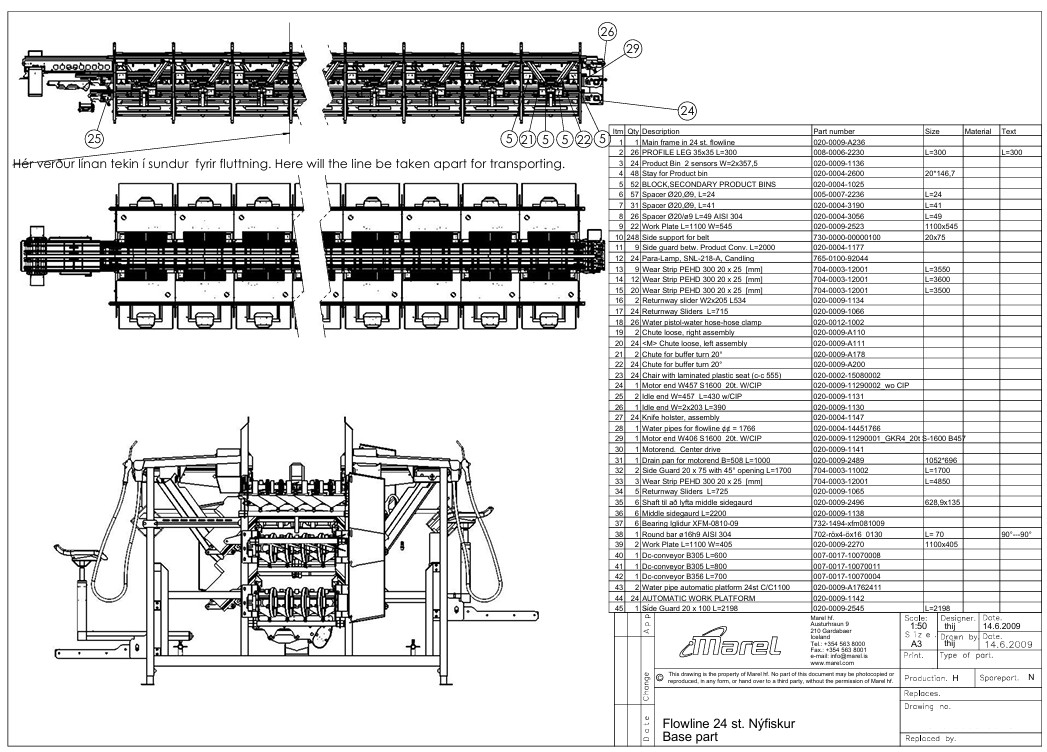

12 working places

Production year 2009

Reconstruction of the line from 24 to 12 places in 2018

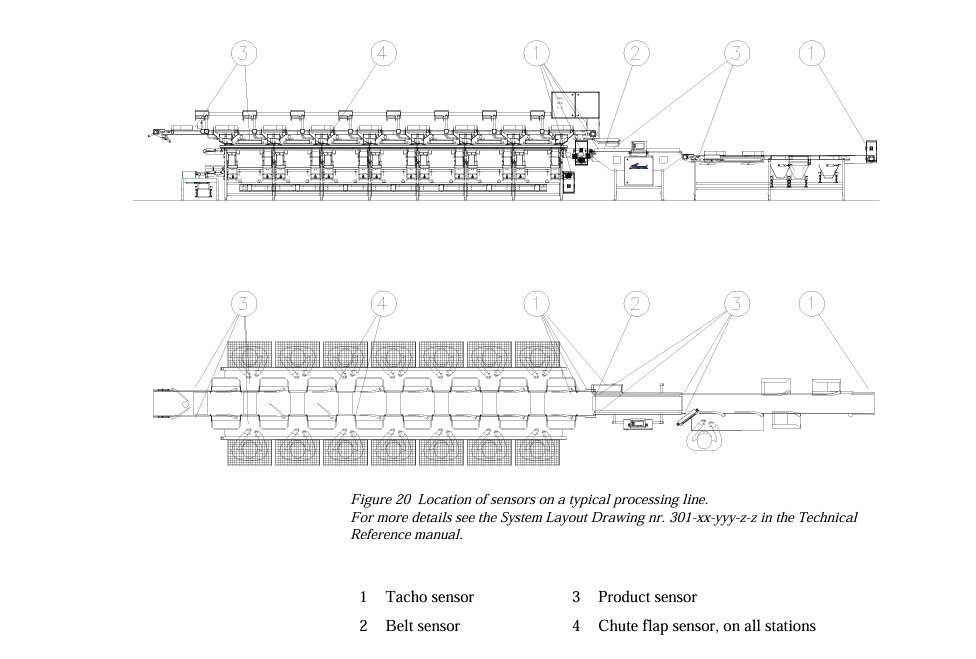

Whitefish Processing Line consists of three main modules, a trimming line with individual operator stations, a weighing unit, and a discharge unit with an optional quality control station.

The line is controlled by the M3000 Controller and MPS production control PC software is used to collect production data, monitor performance, control the flow of raw material, and generate production reports.

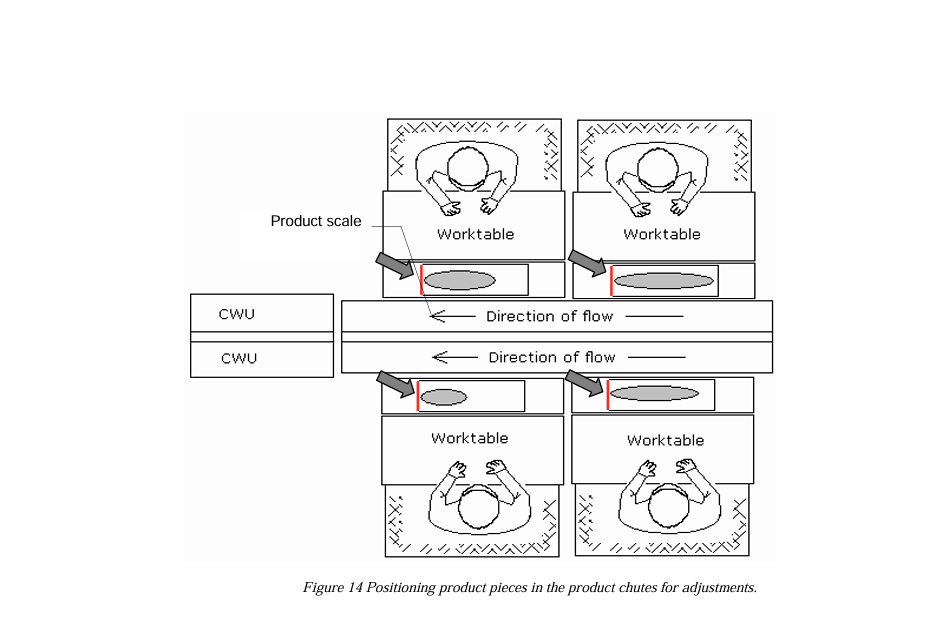

Whole whitefish fillets are distributed to trimming stations on the line where they are trimmed. Specially designed receiving compartments then receive the fully trimmed fillets and slide them gently onto a product conveyor where they are transported to further processing.

Each ergonomically designed trimming station on the Marel Processing Line for Whitefish is equipped with a worktable and bins for products and trimmings. Each operator is individually monitored allowing the implementation of personal achievement systems.

The trimming line is controlled by the MPS Trimming module.

Technical Specifications

| Dimensions: | |

|---|---|

| Outer dimensions | Each operator station approximately 1000 mm in length |

| Weight | Approx. 100 – 150 kg per station |

| Height | Approx. 1100 mm from floor to worktable. Max. height approx. 1700 mm |

| Belt Width | Infeed conveyor belt 356 – 508 mm Product take-away belt 2*203 – 280 mm By-product take-away belt 406 – 457 mm |

| Box volume | Shipped in containers |

| Other | Infeed conveyor: approx. 1500 mm Product take-away belt: approx. 1000 mm By-product take-away belt: approx. 350 mm |

| Construction: | |

| Material | AISI 304 stainless steel, PP, PE, POM plastic |

| Motor type | Drum or gear motors, depending on configuration |

| Belt type | Plastic modular belts |

| Cleaning | Optionally delivered with spraying nozzles for belts |

| Mounting | Bolted to floor |

| Other | Ergonomically designed work area |

| Capacity: | |

| Belt speed | 0.8 – 1.3 m/sec depending on configuration and desired throughput |

| Consumption: | |

| Air | Min. 6 bar |

| Water | Manual water guns on each station For optional self-cleaning |

| Electrical | Less than 2.5 kW |

| Output buffers: | |

| No. output conveyors | 1 product conveyor, up to 2 by-product conveyors |

| No. output buffers | Up to 4 on product conveyor, up to 3 on by-product conveyors |

| Release method | Individual, with sensor or all-at-time periodically |

| Work area: | |

| Standing platform | Manually adjustable (standard) or by water-hydraulics (optional) |