Description

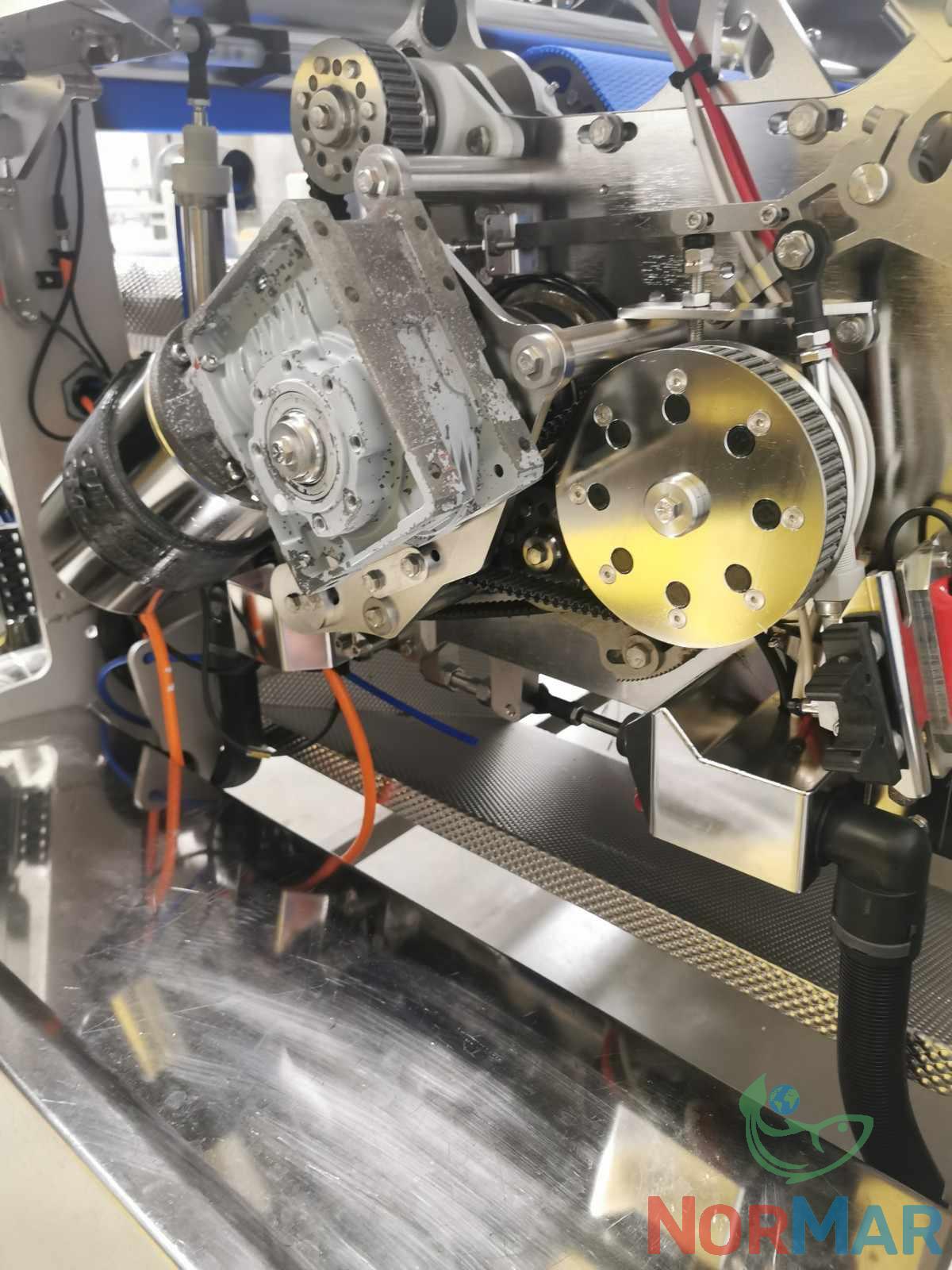

A robust double-skinner, the Curio C2031 skinning machine stands out with its independent control for the right and left conveyors. Its impressive skinning yield is achieved through a combination of a recently engineered skinning roller and an automatic pressure hold-down system, meticulously controlled by sensors. This design ensures the protection of fillets from damage during the skinning process. Additionally, the machine features an electronic measuring system that guarantees the precise skinning of each fillet according to its length.

Operational control and monitoring are streamlined with the Curio 3011 Touch Panel. This interface facilitates the management of machine functions and provides a comprehensive view of both outfeed belts through an integrated camera system. The outfeed belt system is fully height-adjustable, allowing for the gentle delivery of fillets to destinations such as a trimming table or cutting machine. The variable speed of the infeed/outfeed belts enhances operational flexibility.

A notable innovation is the incorporation of an ethernet connection, enabling remote monitoring, maintenance, fault finding, and software upgrades. The machine seamlessly transitions between skin-off and skin-on production when integrated into a processing line.

Constructed entirely from stainless steel and food-grade materials, the Curio C2031 skinning machine prioritizes durability and compliance with hygiene standards.

General Specifications:

- Type: Skinning Machine C2031

- Throughput: 16 – 38 fish/min

Dimensions:

- Length: 2.735m

- Width: 2.400m

- Height: 1.50 – 2.95m

Electrical:

- Input Voltage: 3 phases 380-440V AC.

- Power Rating: 4.0kW

- Current: 9A

Water:

- Water: 36 l/min.

- Pressure: 5 bar

Air:

- Air: 30 l/min.

- Pressure: 8 bar

Condition: In perfect operational condition.